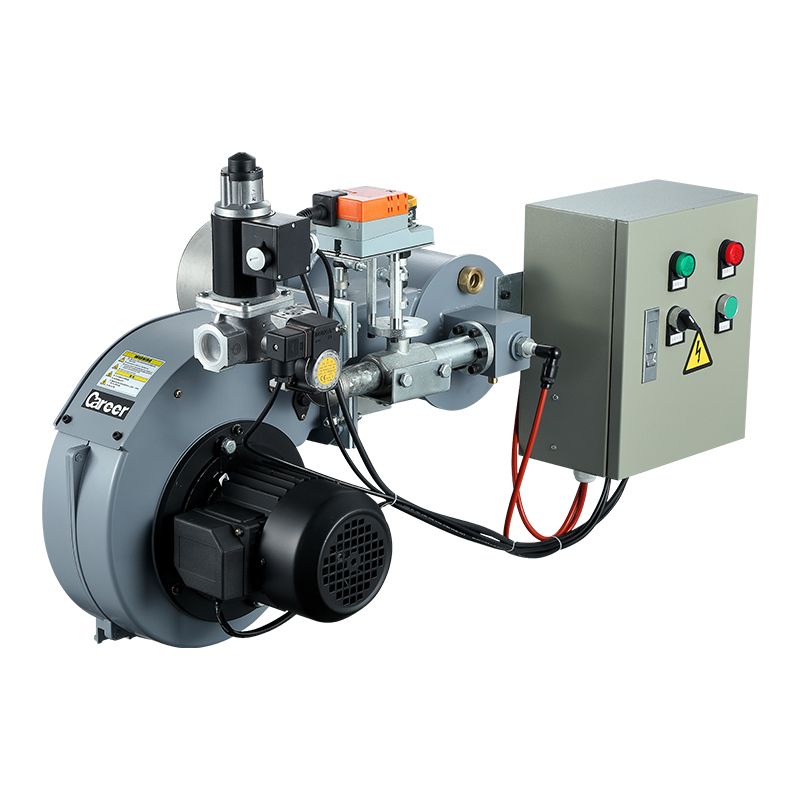

Modern industrial facilities increasingly rely on advanced gas combustion systems to meet their thermal processing needs. Industrial gas burners have emerged as a preferred solution, offering cleaner operation and greater efficiency compared to traditional oil-based systems. Career Burner has positioned itself at the forefront of this technology, developing specialized nozzle-mixing burners that deliver exceptional performance across diverse industrial applications.

Precision Engineering for Optimal Performance

Career Burner’s industrial gas burners incorporate innovative nozzle-mixing technology that ensures complete fuel combustion while minimizing harmful emissions. These systems are designed to accommodate fluctuating thermal demands through their impressive turn-down ratios, maintaining efficiency even during partial load operations. Available in a comprehensive capacity range from 5.3 kW to 348.3 kW, these burners can be precisely matched to specific industrial requirements.

Versatile Applications in Modern Industry

The adaptability of Career Burner’s industrial gas burners makes them suitable for numerous applications, from direct-fired heating in manufacturing processes to precision temperature control in industrial ovens and furnaces. Food processing facilities benefit from their clean combustion characteristics, while chemical and pharmaceutical manufacturers appreciate their ability to meet stringent environmental standards without compromising thermal performance.

Operational Advantages and Cost Benefits

Facilities implementing Career Burner’s industrial gas burners experience significant advantages, including reduced energy consumption and lower emissions output. The durable construction of these systems ensures reliable long-term operation, while their advanced control capabilities allow for precise temperature management. These factors combine to deliver substantial operational cost savings over the equipment’s lifecycle.

Implementation and Long-Term Performance

Successful integration of industrial gas burners requires careful consideration of system specifications and operational parameters. Career Burner provides comprehensive support throughout the installation process, ensuring optimal performance from commissioning onward. Regular maintenance further enhances system longevity and maintains peak efficiency, protecting the investment in this critical equipment.

Conclusion

As environmental regulations become increasingly stringent and energy costs continue to rise, Career Burner remains committed to advancing industrial gas burner technology. Their ongoing research and development efforts focus on enhancing efficiency, reducing emissions, and improving operational flexibility, ensuring their solutions remain at the cutting edge of industrial heating technology.