Automation plays a critical role in modern manufacturing, particularly in industries like battery production. An automated laser cutting table stacker is essential for enhancing efficiency and precision. This equipment streamlines the processes involved in battery stacking machine integration and battery notching, ensuring that companies can meet increasing production demands while maintaining high quality.

Enhancing Workflow Efficiency

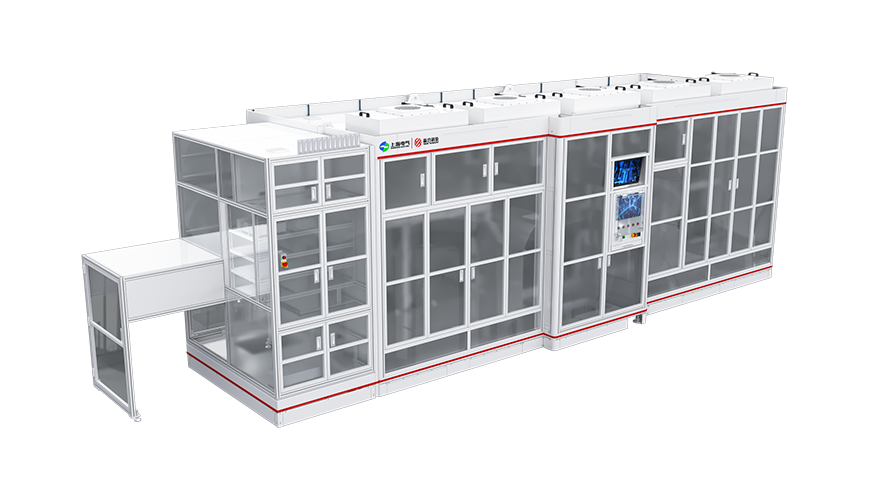

An automated laser cutting table stacker works by automating the cutting process for materials used in battery cell components. The stacker aligns cut pieces for easy handling and transfer, thus reducing manual labor. By integrating with battery stacking machines, it ensures that properly cut materials are fed into the winding process with precision and minimal downtime. The result is a seamless transition from cutting to assembly, which is crucial for maintaining uninterrupted workflow in high-speed production environments.

Reducing Errors in Battery Notching

Precision in battery notching is vital for the overall performance of battery cells. An automated laser cutting table stacker equipped with advanced detection technologies minimizes errors associated with manual processes. With features such as online overhang detection and closed-loop control, these systems ensure that the cutting specifications are met consistently. This level of accuracy translates directly to the quality of prismatic battery cells produced, making it easier for manufacturers to achieve optimal outcomes.

Integration with Battery Winding Machines

The synergy between automated laser cutting table stackers and battery stacking machines cannot be overstated. By ensuring that precisely cut and notched materials are readily available for winding, manufacturers can optimize their assembly line efficiency. For example, prismatic power battery stacking machines with minimal line speed fluctuation (less than ±1) and tension fluctuation (less than ±3%) benefit greatly from the accurate material handling provided by automated stackers.

For businesses looking to streamline their battery manufacturing processes, investing in an automated laser cutting table stacker represents a strategic move. Partnering with reputable equipment suppliers, such as Yinghe, ensures access to advanced solutions that enhance production efficiency and product quality. By leveraging cutting-edge technology, manufacturers can position themselves favorably in the competitive battery market.